Атрибуты продукта

Возможности поставки ...

Атрибуты продукта

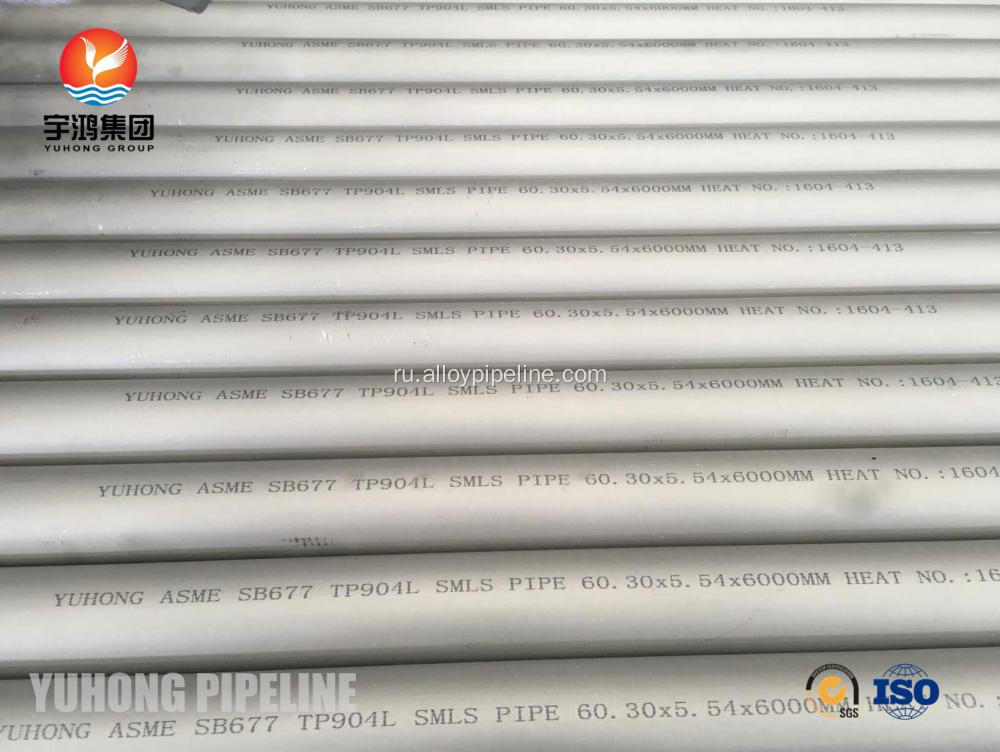

Модель : Stainless Steel Pipe

марка : YUHONG

Описание продукта

%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cstrong%3EASTM+B677+N08904+%2F+904L+%2C+ASTM+B312+N08904+%2F+904L%2C+1.4539%2C+Stainless+Steel+Seamless+Pipes%3C%2Fstrong%3E+%3C%2Fp%3E+%3Ctable0%3E%3C%2Ftable0%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cstrong%3E904L+Stainless+Steel+Pipes+and+Tubes+Product+Range+%3C%2Fstrong%3E+%3C%2Fp%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E%3Cstrong%3E904L+Stainless+Steel+Pipes+and+Tubes+Specifications%3A+ASTM+A%2FASME+SA+269%2F677+904L+Stainless+Steel+Pipes+and+Tubes+Sizes+%28Seamless%29%3A+1%2F2%22+NB+-+8%22+NB%3C%2Fstrong%3E%3Cbr+%2F%3E+%3Cstrong%3E904L+Stainless+Steel+Pipes+and+Tubes+Sizes+%28ERW%29%3A+1%2F2%22+NB+-+24%22+NB%3C%2Fstrong%3E%3Cbr+%2F%3E+%3Cstrong%3E904L+Stainless+Steel+Pipes+and+Tubes+Sizes+%28EFW%29%3A+6%22+NB+-+100%22+NB+%3Cbr+%2F%3E+904L+Stainless+Steel+Pipes+and+Tubes+Wall+Thickness+available%3A%3Cbr+%2F%3E+Schedule+5S+-+Schedule+XXS+%28heavier+on+request%29%3C%2Fstrong%3E%3Cbr+%2F%3E+%3Cstrong%3E+904L+Stainless+Steel+Pipes+and+Tubes+Other+Materials+Testing%3A%3Cbr+%2F%3E+NACE+MR0175%2C+H2+SERVICE%2C+OXYGEN+SERVICE%2C+CRYO+SERVICE%2C+etc.%3Cbr+%2F%3E+904L+Stainless+Steel+Pipes+and+Tubes+Dimensions%3A%3Cbr+%2F%3E+All+Pipes+is+manufactured+and+inspected%2Ftested+to+the+relevant+standards+including+ASTM%2C+ASME+and+API+etc.%3C%2Fstrong%3E%3Cbr+%2F%3E+%3Cstrong%3EKey+Properties%3C%2Fstrong%3E%3Cbr+%2F%3E+These+properties+are+specified+for+flat+rolled+product+%28plate%2C+sheet+and+coil%29+in+ASTM+B625.+Similar+but+not+necessarily+identical+properties+are+specified+for+other+products+such+as+pipe%2C+tube+and+bar+in+their+respective+specifications.%3Cbr+%2F%3E+%3Cstrong%3EComposition%3C%2Fstrong%3E%3Cbr+%2F%3E+%3Cstrong%3ETable+1.%3C%2Fstrong%3E+Composition+ranges+for+904L+grade+of+stainless+steels.%3C%2Fspan%3E+%3C%2Fp%3E+%3Cdiv+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Ctable1%3E%3C%2Ftable1%3E+%3C%2Fdiv%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E%3Cstrong%3EMechanical+Properties%3C%2Fstrong%3E%3Cbr+%2F%3E+%3Cstrong%3ETable+2.+%3C%2Fstrong%3EMechanical+properties+of+904L+grade+stainless+steels.%3C%2Fspan%3E+%3C%2Fp%3E+%3Cdiv+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Ctable2%3E%3C%2Ftable2%3E+%3C%2Fdiv%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E%3Cstrong%3EPhysical+Properties%3C%2Fstrong%3E%3Cbr+%2F%3E+%3Cstrong%3ETable+3.+%3C%2Fstrong%3ETypical+physical+properties+for+904L+grade+stainless+steels.%3C%2Fspan%3E+%3C%2Fp%3E+%3Cdiv+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Ctable3%3E%3C%2Ftable3%3E+%3C%2Fdiv%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E%3Cstrong%3EGrade+Specification+Comparison%3C%2Fstrong%3E%3Cbr+%2F%3E+%3Cstrong%3ETable+4.+%3C%2Fstrong%3EGrade+specifications+for+904L+grade+stainless+steels.%3C%2Fspan%3E+%3C%2Fp%3E+%3Cdiv+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Ctable4%3E%3C%2Ftable4%3E+%3C%2Fdiv%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E%3Cstrong%3EPossible+Alternative+Grades%3C%2Fstrong%3E%3Cbr+%2F%3E+%3Cstrong%3ETable+5.%3C%2Fstrong%3E+Possible+alternative+grades+to+904L+stainless+steel.%3C%2Fspan%3E+%3C%2Fp%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E+%3C%2Fspan%3E+%3C%2Fp%3E+%3Ctable5%3E%3C%2Ftable5%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cstrong%3ECorrosion+Resistance%3C%2Fstrong%3E+%3C%2Fp%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3EAlthough+originally+developed+for+its+resistance+to+sulphuric+acid+it+also+has+a+very+high+resistance+to+a+wide+range+of+environments.+A+PRE+of+35+indicates+that+the+material+has+good+resistance+to+warm+sea+water+and+other+high+chloride+environments.+High+nickel+content+results+in+a+much+better+resistance+to+stress+corrosion+cracking+than+the+standard+austenitic+grades.+Copper+adds+resistance+to+sulphuric+and+other+reducing+acids%2C+particularly+in+the+very+aggressive+%22mid+concentration%22+range.%3Cbr+%2F%3E+In+most+environments+904L+has+a+corrosion+performance+intermediate+between+the+standard+austenitic+grade+316L+and+the+very+highly+alloyed+6%25+molybdenum+and+similar+%22super+austenitic%22+grades.%3Cbr+%2F%3E+In+aggressive+nitric+acid+904L+has+less+resistance+than+molybdenum-free+grades+such+as+904L+and+310L.%3Cbr+%2F%3E+For+maximum+stress+corrosion+cracking+resistance+in+critical+environments+the+steel+should+be+solution+treated+after+cold+work.%3Cbr+%2F%3E+%3Cstrong%3EHeat+Resistance%3C%2Fstrong%3E%3Cbr+%2F%3E+Good+resistance+to+oxidation%2C+but+like+other+highly+alloyed+grades+suffers+from+structural+instability+%28precipitation+of+brittle+phases+such+as+sigma%29+at+elevated+temperatures.+904L+should+not+be+used+above+about+400C.%3Cbr+%2F%3E+%3Cstrong%3EHeat+Treatment%3C%2Fstrong%3E%3Cbr+%2F%3E+Solution+Treatment+%28Annealing%29+-+heat+to+1090-1175C+and+cool+rapidly.+This+grade+cannot+be+hardened+by+thermal+treatment.%3Cbr+%2F%3E+%3Cstrong%3EWelding%3C%2Fstrong%3E%3Cbr+%2F%3E+904L+can+be+successfully+welded+by+all+standard+methods.+Care+needs+to+be+taken+as+this+grade+solidifies+fully+austenitic%2C+so+is+susceptible+to+hot+cracking%2C+particularly+in+constrained+weldments.+No+pre-heat+should+be+used+and+in+most+cases+post+weld+heat+treatment+is+also+not+required.+AS+1554.6+pre-qualifies+Grade+904L+rods+and+electrodes+for+welding+of+904L.%3Cbr+%2F%3E+%3Cstrong%3EFabrication%3C%2Fstrong%3E%3Cbr+%2F%3E+904L+is+a+high+purity%2C+low+sulphur+grade%2C+and+as+such+will+not+machine+well.+Despite+this+the+grade+can+be+machined+using+standard+techniques.%3Cbr+%2F%3E+Bending+to+a+small+radius+is+readily+carried+out.+In+most+cases+this+is+performed+cold.+Subsequent+annealing+is+generally+not+required%2C+although+it+should+be+considered+if+the+fabrication+is+to+be+used+in+an+environment+where+severe+stress+corrosion+cracking+conditions+are+anticipated.%3C%2Fspan%3E%3Cbr+%2F%3E+%3C%2Fp%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E%3Cstrong%3EApplications%3C%2Fstrong%3E%3C%2Fspan%3E+%3C%2Fp%3E+%3Cul+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cli%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3ETypical+applications+include%3C%2Fspan%3E+%3C%2Fli%3E+%3Cli%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3EProcessing+plant+for+sulphuric%2C+phosphoric+and+acetic+acids%3C%2Fspan%3E+%3C%2Fli%3E+%3Cli%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3EPulp+and+paper+processing%3C%2Fspan%3E+%3C%2Fli%3E+%3Cli%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3EComponents+in+gas+scrubbing+plants%3C%2Fspan%3E+%3C%2Fli%3E+%3Cli%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3ESeawater+cooling+equipment%3C%2Fspan%3E+%3C%2Fli%3E+%3Cli%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3EOil+refinery+components%3C%2Fspan%3E+%3C%2Fli%3E+%3Cli%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3EWires+in+electrostatic+precipitators%3C%2Fspan%3E+%3C%2Fli%3E+%3C%2Ful%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E%3Cstrong%3E904L%3Cbr+%2F%3E+Chemical+Composition+%25%3C%2Fstrong%3E%3C%2Fspan%3E+%3C%2Fp%3E+%3Cdiv+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Ctable6%3E%3C%2Ftable6%3E+%3C%2Fdiv%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cbr+%2F%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E%3Cstrong%3EAVAILABILITY%3C%2Fstrong%3E%3Cbr+%2F%3E+Seamless+Pipe+1%2F2%22+W%3Cbr+%2F%3E+SPECIFICATIONS%3Cbr+%2F%3E+ASTM+B677%2C+B366%3Cbr+%2F%3E+ASME+SB677%2C+SB366%3C%2Fspan%3E+%3C%2Fp%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cbr+%2F%3E+%3C%2Fp%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E%3Cstrong%3EDESIGN+FEATURES%3C%2Fstrong%3E%3Cbr+%2F%3E+Good+resistance+to+pitting+and+crevice+corrosion.%3Cbr+%2F%3E+Very+good+resistance+to+stress+corrosion+cracking.%3Cbr+%2F%3E+Good+resistance+to+intergranular+corrosion.%3Cbr+%2F%3E+Good+formability+and+weldability.%3Cbr+%2F%3E+Maximum+service+temperatures+of%3Cbr+%2F%3E+450+deg.C.+%28824+deg.F%29.%3C%2Fspan%3E+%3C%2Fp%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E%3Cstrong%3ETYPICAL+APPLICATIONS%3C%2Fstrong%3E%3Cbr+%2F%3E+Production+and+transport+of+sulfuric+acid%3Cbr+%2F%3E+Metal+pickling+in+sulfuric+acid%3Cbr+%2F%3E+Production+and+concentration+of+phosphoric+acid%3Cbr+%2F%3E+Use+in+seawater%2C+brackish+water%2C+condensers%2C+heat+exchangers+and+pipe+work+in+general%3Cbr+%2F%3E+Paper+and+allied+industries%3Cbr+%2F%3E+Gas+washing%3Cbr+%2F%3E+Chemical+and+pharmaceutical+industries%3C%2Fspan%3E+%3C%2Fp%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cspan+style%3D%22font-family%3Aarial%2C+helvetica%2C+sans-serif%3B%22%3E%3Cstrong%3ETENSILE+REQUIREMENTS%3C%2Fstrong%3E%3Cbr+%2F%3E+Tensile+Strength+%28KSI%29+70%3Cbr+%2F%3E+Yield+Strength+%28KSI%29+25%3Cbr+%2F%3E+KSI+can+be+converted+to+MPA+%28Megapascals%29+by+multiplying+by+6.895.%3C%2Fspan%3E+%3C%2Fp%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cstrong%3ESome+of+the+quality+tests+carried+out+by+us+includes%3A%3C%2Fstrong%3E+%3C%2Fp%3E+%3Ctable7%3E%3C%2Ftable7%3E+%3Cp+style%3D%22color%3A%23333333%3Bfont-family%3Aarial%3Bfont-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E+%3Cbr+%2F%3E+%3Cstrong%3ESupplementary+Testing+%3A+%3C%2Fstrong%3EApart+from+the+above+mentioned+tests%2C+we+also+carry+out+on+the+manufactured+products+supplementary+testing.+The+tests+conducted+under+this+include%3A+%3C%2Fp%3E+%3Cp%3E+%3Ctable8%3E%3C%2Ftable8%3E+%3C%2Fp%3E+%3Cp%3E+%3Cspan%3E%3Cspan+style%3D%22font-size%3A14px%3Bbackground-color%3A%23FFFFFF%3B%22%3E%3Cimg+src%3D%22%25oss_domain%25product%2Fc9%2F75%2Ff3%2F50d157216e76f37155d7d23f54.jpg%22+width%3D%22300%22+height%3D%22224%22+title%3D%22B677+904L+Smls+Pipe%22+alt%3D%22B677+904L+Smls+Pipe%22+%2F%3E+%3Cimg+src%3D%22%25oss_domain%25product%2F1d%2Fa5%2Fe9%2F5476f66f62f57d32dd7427955b.jpg%22+width%3D%22300%22+height%3D%22225%22+title%3D%22904L+stainless+steel+pipes%22+alt%3D%22904L+stainless+steel+pipes%22+%2F%3E%3C%2Fspan%3E%3C%2Fspan%3E+%3C%2Fp%3E+%3Cp%3E+%3Cimg+src%3D%22%25oss_domain%25product%2Faa%2Fd3%2F82%2F9502ea8f6c57a7a7994dadc407.png%22+width%3D%22300%22+height%3D%22226%22+title%3D%22A312+TP904L+Seamless+Pipes%22+alt%3D%22A312+TP904L+Seamless+Pipes%22+%2F%3E%3Cspan+style%3D%22background-color%3A%23FFFFFF%3Bfont-size%3A14px%3B%22%3E+%3C%2Fspan%3E%3Cimg+src%3D%22%25oss_domain%25product%2Faf%2F8a%2F42%2F9595888e883d07bcb35dc8de86.jpg%22+width%3D%22300%22+height%3D%22226%22+title%3D%22Alloy904L+stainless+steel+seamless+pipes%22+alt%3D%22Alloy904L+stainless+steel+seamless+pipes%22+%2F%3E+%3C%2Fp%3E+%3Cp%3E+%3Cbr+%2F%3E+%3C%2Fp%3E

Упаковка и доставка

Продажа единиц жилья

:

Kilogram

Тип упаковки

:

Ply-wooden Case /Iron Case/ Bundle with plastic Cap

The file is encrypted. Please fill in the following information to continue accessing it

Возможности поставки и дополнительная информация

Подробности Упаковки : Ply-wooden Case /Iron Case/ Bundle with plastic Cap

транспорт : Ocean,Land,Air

Место происхождения : CHINA

Сертификаты : ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2008

Порт : Shanghai Sea Port,Ningbo Sea Port

Вид оплаты : L/C,T/T

Инкотермс : FOB,CFR,CIF